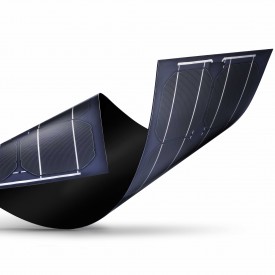

Sunflare recently introduced its mass-produced, flexible CIGS solar panels using its Capture technology.

“Sunflare has worked for six years to perfect Capture, a cell-by-cell manufacturing process with the highest degree of precision and the cleanest environmental footprint,” said Philip Gao, Sunflare’s CEO. “This allows us to do what no manufacturer of CIGS thin film has done before –mass produce efficient, flexible solar panels.”

Compared to crystalline silicon, Sunflare is flexible because it does not use a glass substrate and has thinner layers of semiconductors. It requires less energy to manufacture and does not use toxic chemicals. Compared to crystalline silicon, Sunflare captures 10 percent more energy from dawn to dusk, the supplier stated.

Sunflare is more than 65 percent lighter than silicon modules. This allows the entire roof to be covered without weight concerns. Additionally, it does not require an aluminum frame, nor does it require building penetration.

The National Renewable Energy Laboratory declared in a recent report that due to tax credit extensions, the U.S. is projected to add 53 additional gigawatts of renewable energy capacity by the year 2020. The U.S. Energy Information Administration expects solar to achieve the greatest increases, adding 9.5 gigawatts of utility-scale solar in 2016.