RV Help Adds New Features to Mobile App

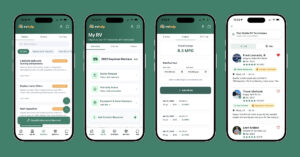

RV Help, a platform connecting RV owners with certified mobile service technicians, announced an update to its mobile app to launch powerful new features designed to help RV owners stay on top of maintenance, avoid costly repairs and keep critical RV documents at their fingertips.

The upgraded app transforms RV Help from a service directory used for emergency repairs into an indispensable daily companion for the estimated 11.2 million RV-owning households in America, with additional in-app educational content being added in spring of 2026, RV Help said in a release.

“Our goal from the beginning has been to help RV owners prevent costly repairs, not just react to them,” said Josiah Mann, technical co-founder of RV Help. “The new app features help owners stay on top of routine maintenance and catch small issues before they become expensive problems.”

The new features include maintenance tracking and reminders based on manufacturer recommendations for tasks like roof resealing and air conditioner servicing, fuel logging to monitor efficiency and track costs, and a virtual glovebox that stores manuals, warranty information and service records in one accessible location. In spring of 2026, the app will add an educational content library with how-to articles and instructional videos for each maintenance task.

Getting RV Owners Faster Service

RV Help’s primary mission remains centered on reducing the time RV owners spend waiting for repairs. The platform connects owners with vetted mobile RV service providers who come directly to campsites, driveways and storage lots, eliminating wait times that can stretch for weeks or months, the company said. The app also features remote service options like virtual troubleshooting to help RV owners avoid a service call and get back on the road faster.

Core Features Free, Premium Upgrades Available

The RV Help app is free to download and use, with all basic features, including maintenance tracking, fuel logging, and the ability to find and book service, available at no cost. When the educational content library launches in spring 2026, free users will have access to articles and select videos. RV Help Pro memberships unlock premium features including unlimited document storage, exclusive video tutorials, virtual troubleshooting and other premium service options, and enhanced maintenance tracking customization.