Parts Department Storage Best Practices To Boost Productivity & Sales

Is your parts department storage room organization on par with your showroom? It should be.

The December issue of RV PRO for 2025 focuses on the interiors of RVs. This caused me to think about the interiors of parts departments and the parts department storage. During my career as a retail parts manager, I was hired to improve the performance of the parts operations. In most of these departments, the retail showroom was reasonably attractive and organized — at least at first glance.

However, when I walked behind the slat walls into the storage area, it was usually a completely different story. There was clutter. Beverage containers often occupied spaces in the storage units. Opened cartons might be lying about on the floor. Items might be in more than one storage location — and not intentionally. These conditions needed to be improved, and they were.

After changing my career path to start P.A.R.T.S. in 1990, I applied my experience as a parts manager to my new career as a consultant and trainer. One of the training workshops that I developed focused on the interior of the parts department and how it often contrasted with the retail showroom area. I named this situation “The Facade Fallacy.”

What Could You Do?

If you have been reading my columns, you know that my suggestions usually require you to do some work. This one is no different, so try this before reading further: Walk into your parts storage room/area and look around. Does it look cluttered? Are there empty shelves/spaces? Are items on the floor? Are beverage containers sitting in the storage units? If you have answered yes to any of these questions, I suggest reading the remainder of this column.

STORAGE: Some Useful Concepts

Since we are working in your storage room/area, I have decided to provide some recommendations based on each letter in the word “storage.”

Size/quantity is a concept that could provide you with more room in which to store your parts and accessories goods. Many storerooms have the shelving spaced the same distance apart, yet this is not an effective use of the storage volume. I suggest placing items of the same size (especially same/similar height) on the same shelf and spacing the shelves to accommodate the various sizes of the items.

Trash containers: To keep the area clear of trash, we used empty shipping cartons with trash can liners. These cartons were placed at the end of each shelving row and in other areas of the storeroom. When the cartons became flimsy, we recycled the cardboard and replaced that unit with a fresh carton.

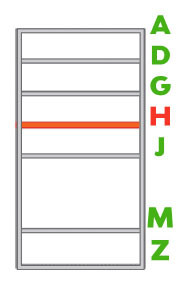

Organized by bin location: Since most of the parts and accessories in the storage room/area were placed according to size/quantity, it was important to assign a bin location to each item so it could be easily retrieved and/or stocked. I suggest using my skipped letter/number bin location format to accommodate the changes to your inventory mix. As shown in the figure to the left, my skipped letter/number concept requires that letters (or numbers) be skipped when assigning bin locations to goods stored in a unit. This enables easy updates to the bin locations when a shelf needs to be added to a storage rack. In this example, when shelf H is added, it will not be necessary to change the bin locations of any items already on shelves above H or below H. This saves time and minimizes errors in retrieving and placing goods. A is always the top shelf and Z is always the bottom shelf.

Organized by bin location: Since most of the parts and accessories in the storage room/area were placed according to size/quantity, it was important to assign a bin location to each item so it could be easily retrieved and/or stocked. I suggest using my skipped letter/number bin location format to accommodate the changes to your inventory mix. As shown in the figure to the left, my skipped letter/number concept requires that letters (or numbers) be skipped when assigning bin locations to goods stored in a unit. This enables easy updates to the bin locations when a shelf needs to be added to a storage rack. In this example, when shelf H is added, it will not be necessary to change the bin locations of any items already on shelves above H or below H. This saves time and minimizes errors in retrieving and placing goods. A is always the top shelf and Z is always the bottom shelf.

Rate of transactions is another factor to consider when determining where to place the parts and accessories in your storage room/area. To minimize the time and steps needed to retrieve the most frequently transacted goods, you might want to place them closest to the retail workstation(s). If you have a separate workstation to support the service technicians, you might have a separate storage unit containing those goods that the technicians frequently request.

Age of the goods, especially those that have not incurred a transaction in 12 months or more, might need to be eliminated from your inventory. This frees up room and money to add items that might be more in demand. Having a selection of items currently in demand minimizes the need to special order items or to incur a lost sale if the customer chooses not to place an order.

Gross sales are partly driven by the quantity of transactions that are processed by your parts associates. If goods are in clearly defined bin locations, then your parts associates can retrieve them quickly and process the transaction efficiently. If items frequently requested at the same time are stored near each other, then that also speeds up the transaction. You could also place reminders to your parts associates to recommend related items to the customer.

Efficiency of the parts transactions can also improve the morale of your parts associates because they don’t have to take extra steps to process most of the transactions. If your parts associates are paid a commission on their gross sales (assuming they are achieving a minimum gross profit), they have an opportunity to process more transactions and earn more income.

These are a few of the factors that could be considered when organizing your parts and accessories storage room/area. It is not necessary to include each of them, nor is it necessary to do them all at once. For instance, you might decide to identify those items that are most frequently transacted and relocate these items as close to the retail and service workstations as possible. If you notice an improvement in the parts associates’ morale and possibly in your gross sales, maybe try another suggestion. In the words of that Oklahoma native Will Rogers: “Even if you’re on the right track, you’ll get run over if you just sit there.”