Blog: Optimizing Your Service Department Using Automation: Data Entry

The following is the second of a three-part blog series from Frank Tamburrini, president and general manager at Integrated Dealer Systems. Part one is here, and part three will air Wednesday.

Every dealership is different. That means every service department will have its own unique set challenges to overcome.

But after talking with hundreds of different dealers across North America, our team at IDS have noticed some trends emerge. From those conversations, we’ve identified nine of the most common bottlenecks experienced in service department.

The kicker? Many of those bottlenecks can be fixed by automating the most time-consuming, frustrating parts of your service department processes.

In part one of this series, I talked about how you can streamline communications within your dealership and with your customers. In this installment, I’m going to cover a most dreaded topic: data entry.

If you haven’t read part one of this dealership service automation series, click here to jump back.

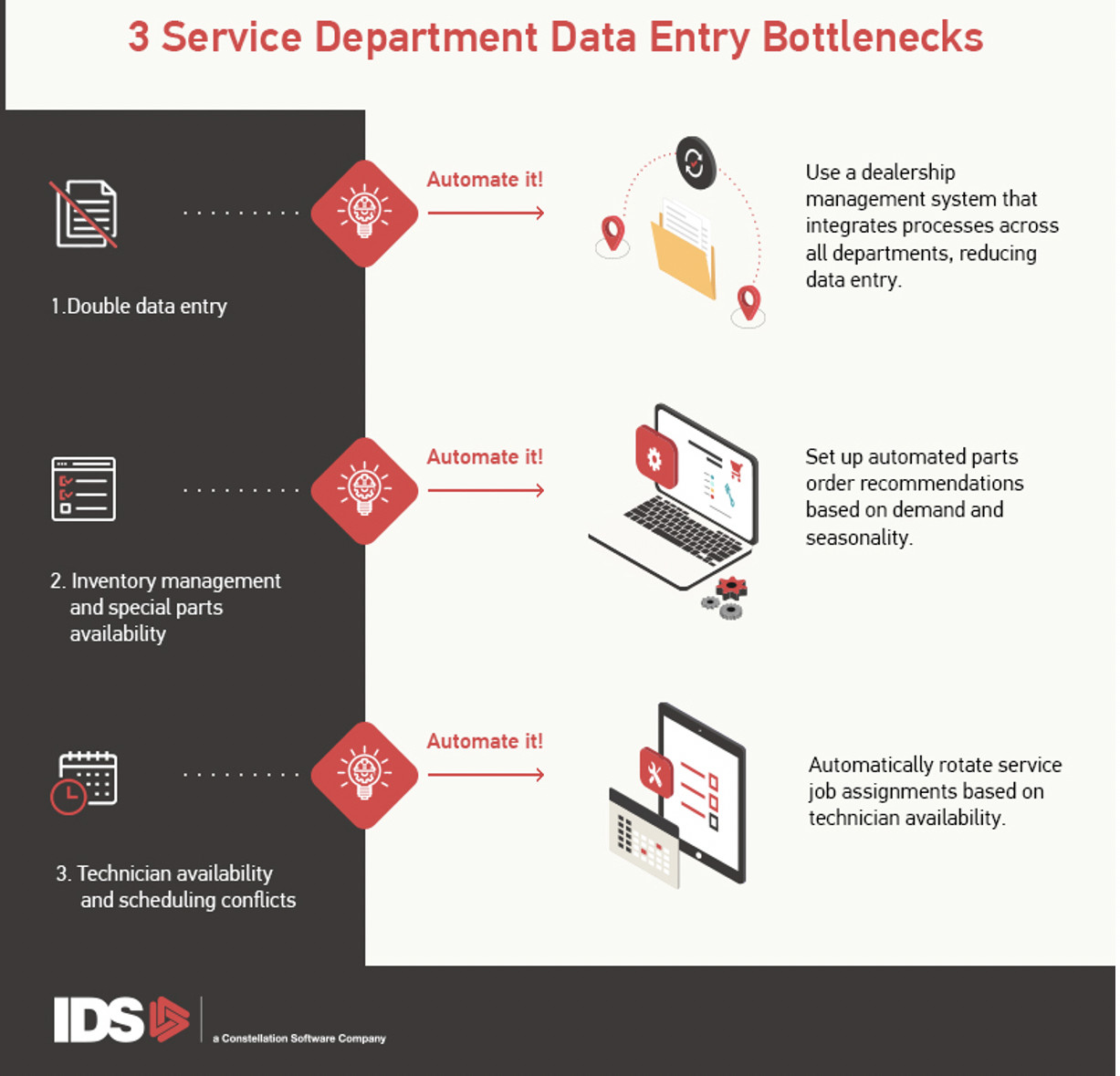

Service Bottleneck: Double Data Entry

Does your team need to flip between multiple spreadsheets, forms, and programs? If yes, then your team probably needs to enter the same information in multiple places, multiple times…or you need to have someone on staff to handle it.

But you can save time and money by integrating your department data and automating data entry.

Automate It!

Instead of stitching together multiple systems, have all roads lead to the same place. By using a dealership management system (DMS), your data can automatically flow from your sales, service, and F&I departments right into your accounting system. For example, when a customer makes a payment, you can automate the event so that your AR account is automatically updated with the payment.

That means less data entry and less room for errors—which means less back-and-forth between departments. It’s a triple-win.

Service Bottleneck: Inventory Management and Special Parts Availability

Many dealerships are still using a clipboard to manage their inventory numbers. That means a lot of time spent manually updating information, with plenty of room for error.

This can lead to unexpected parts shortages and miscommunications between your sales and parts department about which parts are available, when parts will be delivered, and other headache-inducing situations.

Automate It!

Automate parts order recommendations based on demand and even seasonality—so you’re only ordering the parts you need when you need them.

If you have an efficient inventory management system in place, you can easily stay on top of inventory numbers. Plus, you will be able to keep your parts moving, while ensuring that you’re not over-or under-ordering certain parts.

Service Bottleneck: Tech Availability and Scheduling

When your technicians are all busy, it can be tough to decide which team member should be assigned a job.

That’s why having an efficient, up-to-date work schedule is crucial. Scheduling allows you to control how many customers come in on a given day and when. This gives your service team the bandwidth to spend quality time with each customer.

But maintaining a detailed calendar is a full-time job. Automation can help with this.

Automate It!

Integrate your department calendars to make scheduling a seamless process. For example, you can configure tech scheduling so that jobs are automatically assigned to whichever tech is available. Having one central location for your schedules also makes it easy for anyone on the team to check what is being worked on and by who.

We’re Not Done Yet!

There are still three more common RV dealership service department bottlenecks to cover. In part three, I’ll round out the series by talking about the bottom line.

Click here to read Part One of this three-part series.

Frank Tamburrini is the president and general manager of Integrated Dealer Systems, a leading RV dealership software provider. He has over 20 years of experience helping customers in different industries improve their customer experience and operations through technology but is a firm believer that technology is only part of the solution; it’s the people using the technology, the commitment for continual improvement and being data-driven that makes the real difference.