Getting RV Propane Systems Right

Proper LPG calibration, regulator sizing and technician training help keep your customers safe on the road.

The RV industry has relied heavily on liquefied petroleum gas (LPG) — or propane — to power appliances that assist us in heating, cooking and bathing in our RVs. This relatively clean and economical fuel makes good sense for the consumer as it performs well and enables modern conveniences, whether camping where there are full hook-ups available or when camping remotely.

As the use of LPG-powered appliances in today’s market have increased over the last 20 years, so too has the need for RV technicians to better understand how supply systems are designed and how their performance parameters are affected by the use of advancing appliances. The critical steps in the setup and calibration processes are essential to the system’s performance and safe operation.

A key part of the calibration process is understanding what demands are placed upon the supply system. Much like understanding the electrical loads placed on a power supply system, knowing the flow demand of propane appliances when they are in operation is important in adjusting the regulator properly. This is all done according to processes and procedures outlined in the RV Technical Institute training program. Additional support is often provided by supplier field personnel hosting trainings on-site.

Regulators

Sizing of regulators is also important. To illustrate this issue, we can draw a parallel with the electrical system. With the increase in electrical appliances over the years, upgrading the electrical supply lines was necessary. Hence, power cords rated at 15 amperes, once standard equipment on RVs, gave way to power cords with a 30 amperes rating and eventually to those with 50 amperes rating. This all was mandatory as the electric appliance demand grew.

The same is true for propane in the RV industry. A few examples where the LPG demand has grown on RVs include the use of outdoor kitchens, instant hot water heaters and portable gas grills. Such expansion requires assessing existing supply lines, and that starts with the regulator. There is no “one size fits all” when it comes to electrical supply, and this is true on the LPG side as well. A smaller trailer with minimal appliances will have a completely different demand than a large fifth wheel with more amenities and propane appliances.

Assuring the regulator is the proper size to meet demand is important, keeping in mind that with propane, oversizing a regulator can have as many challenges with performance as when you undersize a regulator. Both can create poor performance issues and, at times, might create a safety issue.

Many times, service departments may not be aware of the problems. After all, customers may not complain of poor performance, as they often don’t recognize the problems experienced with poorly calibrated systems. Consumers may simply think, “Well, it’s an RV. It just takes longer to boil water on these weaker systems than at my home.”

The problem is not the RV — it is the setup of the LPG system and/or its components.

The more noticeable issues are when appliances go into fault mode when proper flow is not available and/or restricted, often causing the appliance operation to be questioned by the consumer, when unknowingly it is the LPG supply system all along.

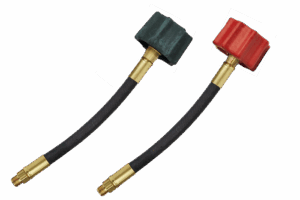

Hoses & Valves

Regulators are not the only important link in the chain. Hoses are just as important. Matching up the proper excess flow check valve to each system’s needs can have just as much effect on performance as the regulator.

Excess flow check valves are there for safety. Each check valve is designed to cut off supply when the flow exceeds an amount deemed excessive for that system. This is especially important in mobile systems as the vibrations and such while traveling can have negative effects at times. If, for example, one of the supply lines was sheared from an accident, LP gas might start escaping in high volume and provide fuel for a fire, creating an emergency situation.

When an excess flow valve is installed on the supply side of the regulator, it would detect this “excessive” amount of demand, much greater than what any normal use would create, and the check valve would shut down the flow automatically.

When the properly designed hose is not used, it can create either a performance problem with the RV’s appliances or a potentially unsafe situation.

The Importance of LPG Training

LPG has become a valuable source of fuel for RVers because it is clean, reliable and supports the independent travel and use applications so often desired by the lifestyle RVers enjoy. Yet that performance is often challenged when the system is not calibrated properly and/or the components used are not matched up to the needs of the application.

RV technician training and supplier-based support is paramount to RV service shops delivering a superior performance to the RV consumer on a variety of categories and is especially true when it comes to LPG systems.

Knowledgeable technicians are key to not only delivering this performance to the consumer — but they are also essential in ensuring systems are set up properly and limiting liability exposure for the dealership overall. Certification is as important as is who you choose as your propane system supplier.