RECTifying Your Operations, Part 2

How collaboration between parts associates and service technicians can benefit your customers and your dealership’s efficiency.

Editor’s note: This is the second part of a series highlighting repair event cycle time (RECT). Part 1 appeared in the July 2024 issue of RV PRO magazine and can be found here. In the first installment of this series, we looked at one side of our six-sided box. I suggested that you review at least one of your fixed ops processes, specifically your service special tool control policies and procedures. Perhaps I tempted you to use the research into this process to determine if you could reduce your RECT by modifying your detailed written procedure (DWP) for this process. If you have done this, I hope your efforts were rewarded by identifying opportunities to reduce your RECT.

Whether you have realized ways to reduce your repair event cycle time (RECT) or not, I suggest that you continue reading this month’s column, which will look at two more sides of our idea box which are:

Service Tech Parts Associate (STPA) — which is a parts associate dedicated to support the technicians.

The Tech Walk — a review of possible steps taken by a technician in the acceptance of, processing of and completion of a work order; a tool to evaluate the costs related to a technician’s time while walking during the work order process.

The Second Side — STPA

In the latter part of my parts manager/director career, I was fortunate to be hired at a dealership that incorporated a portion of the STPA position. There was one parts associate assigned to research, determine price and availability, and issue parts, accessories and materials to the technicians. This associate worked at a designated workstation to which only service personnel had access. This reduced technician wasted time, or W-Time, which reduced overall RECT.

I realized the benefits of this position not only to the service department but also to the parts department and eventually to the customers. I decided that we could benefit even more if we added responsibilities to the position, which were:

- Communicate with the service person who dispatched the work so that the research and procurement aspects of the position could be done in advance whenever possible; this communication with the dispatcher** was scheduled to be performed at least every two hours for the current and next day’s jobs.

**This might not be a specific person; it could be the service manager, service adviser or other nontechnical person familiar with the workflow and each technician’s skills. - Communicate with the dispatcher to determine when a job was to be issued to the technician so that any prepulled goods could be delivered to the technician’s workstation, which minimized some of the technician’s walking, during which no income was being generated.

- Communicate with the technician when delivering the goods regarding what else might be required, which enabled the STPA to research these items without having the technician stop their work to do this — and communicating with other technicians to determine their additional needs during this delivery cycle.

Perhaps you noticed that each of the STPA tasks involved communication. This introduces another variation on RECT — Routinely Efficient Communication Techniques. By improving this RECT, you have an opportunity to reduce the RECT.

At this point, some of you might be asking how I expect you to justify this extra position. Depending on the number of technicians in your shop and the average duration of a job, this could be performed by any of your parts associates on an as-needed basis — assuming the communications I have suggested are efficiently processed. Or you could calculate the income opportunities that exist by reducing the unnecessary steps that your technicians are taking each shift, which could justify a dedicated STPA. Which is the third side of our box: The Tech Walk.

The Third Side: The Tech Walk & Related W-Time

Each of your shops are different in regard to their size, the number of techs, the distance from the farthest tech bay to the parts department and other factors, so I am going to make some assumptions, which are:

- The service bays are in the same building as the parts department and the service adviser(s) workstation(s)

- There are four technicians each with a separate work bay

- The tech walking the farthest from the service adviser workstation and the parts department has a 125-foot one-way walk

Please increase or decrease these factors based on your RV business.

In our Tech Walk scenario, there are eight possible paths that the technician might have to take before starting the work order. Some may seem unrealistic; however, if you observe your technicians on a routine day, I think you might be surprised at the W-Time accumulated.

- Tech walks to the service adviser/dispatcher to get the work order and reviews requested work.

- Tech walks to the lot to retrieve the unit and answers an employee’s question.

- Tech walks to retrieve the unit, but the key isn’t in it so the tech walks back to the service adviser.

- Tech gets the unit and drives it to the work bay.

- Tech walks to the parts department to get parts, stock and/or a special order and any other needed materials.

- Tech carries parts/materials to the bay and gets stopped by another tech who has a question about a work order.

- Tech continues to the work bay.

- Tech realizes a special tool is required and walks to the special tool storage area and then returns to the work bay.

And this is just to get the technician started on the work order.

In your RV business, other people may perform these trips, such as a lot porter who might deliver the RV to the tech’s bay. This is a good example of having support personnel reduce these trips. However, many of these trips are taken by your technician, who isn’t earning you any income during these walks. So consider that an STPA could be doing a lot of these support tasks.

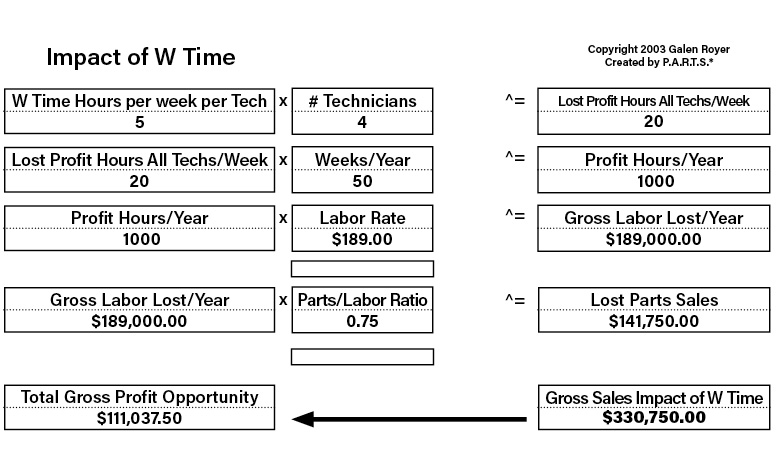

I have provided an example of how much these walks could be costing you (see chart on page 46). The data I used is for example only. If you would like a copy of the Excel tool that I used for this example, please contact me via email.

My assumption is that each of the technicians in the example only expends one hour of W-Time per workday, making it is easy to justify the expense of an STPA. Add the benefit that by reducing the W-Time for each technician, it opens more time available that you can sell. This could improve your customer service by providing a greater opportunity for a customer to have their RV serviced when they want it. And if each technician is more efficient, then maybe you don’t need as many technicians.

Perhaps I have piqued your interest enough to consider either or both of these sides of the idea box. In the September issue, I will offer two more sides outside of the box to reduce your RECT.